Adhesive for foamed polystyrene and XPS and for execution of the reinforced layer. 2 in 1 - it is designed for fixing thermal insulation panels and for execution of the reinforced layer in thermal insulation of buildings technology. Element of thermal insulation systems – it is a part of composite thermal insulation systems, awarded with European (ETA) technological approvals. Enables fixing various expanded and extruded polystyrene boards - including expanded polystyrene boards with addition of graphite and elasticized.

- high adhesiveness

- good water vapor permeability

- reinforced with microfibres

- resistant to cracks and scratches

- for bare and rendered walls

Types of construction substrates:

- all classes of concrete,

- aerated concrete,

- cement

- plaster,

- cement-lime plaster,

- sandstone and bare walls made of brick,

- blocks,

- hollow brick and other similar ceramic or silicate materials.

Properties:

- Elastic – compensates strain resulting from the influence of temperature and usage upon other layers of the system.

- Increased resistance to cracking – it is reinforced with cellulose fibres.

- Highly adherent – strongly adheres to difficult substrates, e.g. substrates covered with strongly adhering paint coats.

- Vapor permeable – does not limit the flow of water vapor through the insulated partition.

Consumption:

Individual consumption of the adhesive depends on the properties of the substrate (its evenness among others) and on the accepted technology of fixing the panels.

- Fixing boards: from 4.0 to 5.0 kg/m2

- Reinforced layer installation: from 3.0 to 3.5 kg/m2.

Packaging:

Paper bags: 25 kg

Pallet: 1200 kg in 25 kg bags

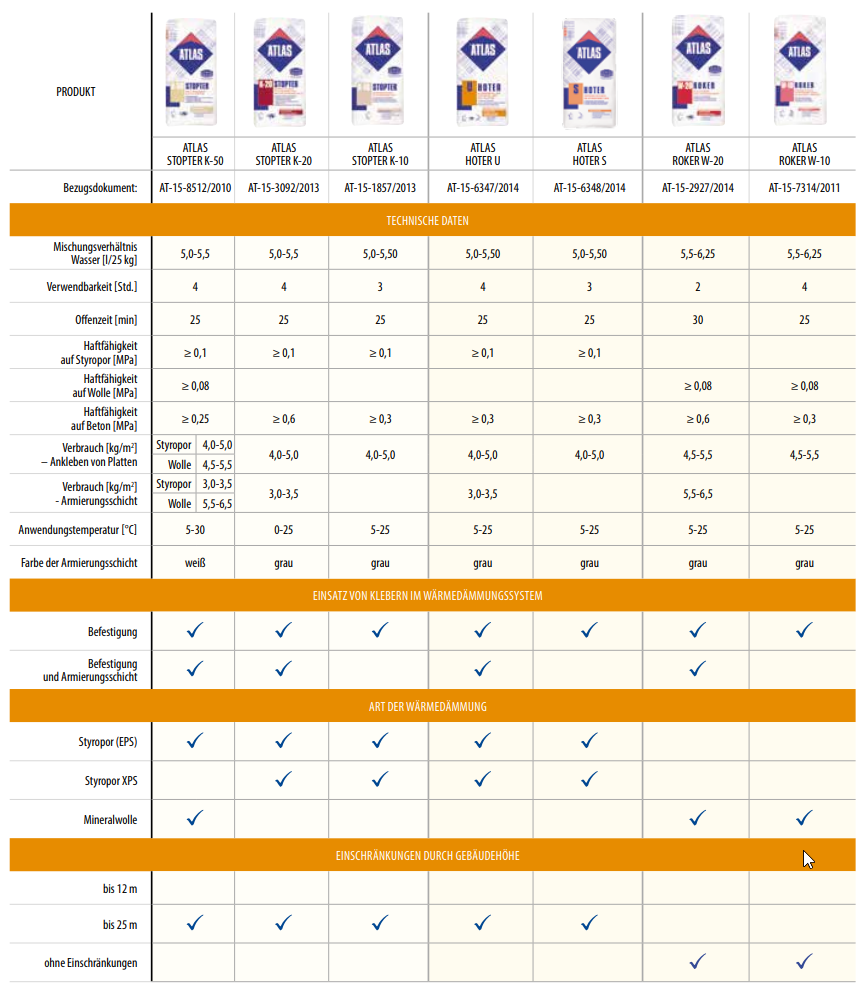

Product comparison

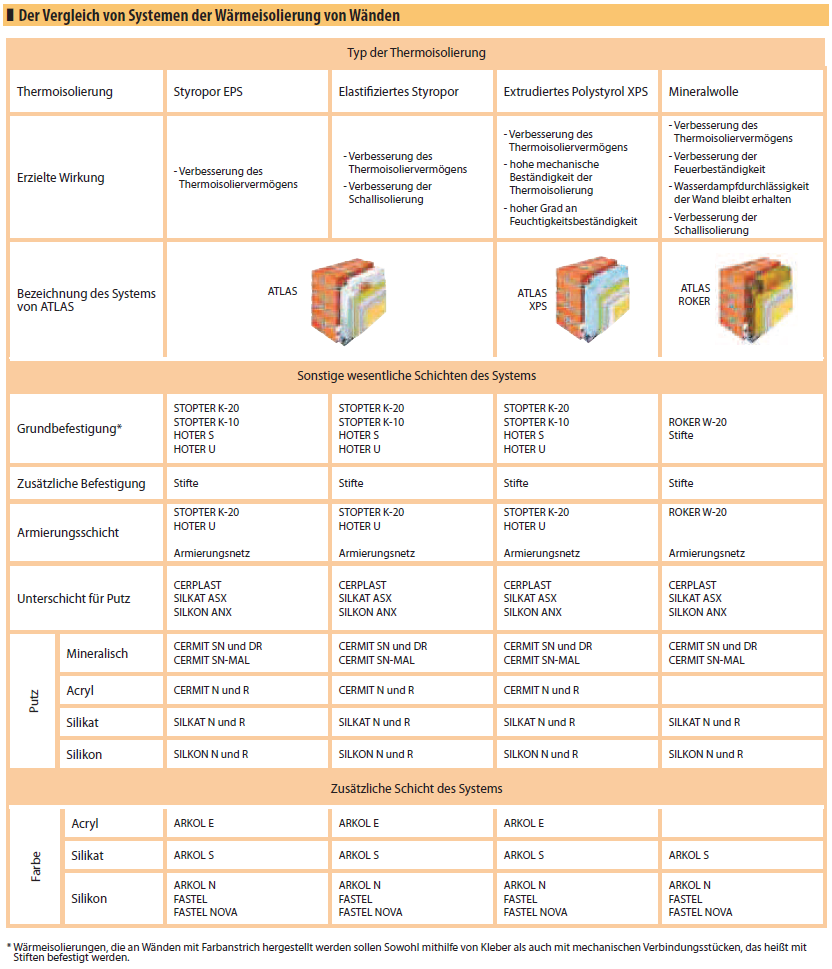

| Stopter K-50 | Stopter K-20 | Stopter K-100 | Hoter U | Hoter S | Grawis U | Grawis S | Roker U | Roker W | |

| Insulation aplication | + | + | + | + | + | + | + | + | |

| Mesh embedding | + | + | + | + | + | + | |||

| Type of insulation | |||||||||

| EPS | + | + | + | + | + | + | + | ||

| XPS | + | + | + | + | |||||

| Mineral wool | + | + | + | ||||||

| Parameters | |||||||||

| Adhesion to concrete | min. 0,25MPa | min. 0,25MPa | min. 0,25MPa | min. 0,25MPa | min. 0,25MPa | min. 0,25MPa | min 0,25MPa | min 0,25MPa | |

| Adhesion to insulation products | min. 0,08MPa (EPS) min.0,08MPa (MW) |

min 0,08MPa | min. 0,08MPa | min. 0,08MPa | min. 0,08 MPa | min. 0,08MPa | min. 0,08MPa | min. 0,08MPa | min 0,08MPa |

| Temperature of application | 5° to 30°C | 0°C to 25°C | 5°C to 30°C | 5°C to 30°C | 5°C to 30°C | 5°C to 30°C | 5°C to 30°C | 5°C to 30°C | 5°C to 30°C |

| Height limit for application | |||||||||

| EPS, XPS | to 25m | to 25m | to 25m | to 25m | to 25m | to 25m | to 25m | ||

| Mineral wool | no limit | no limit | no limit | ||||||

- Atlas sp. z o.o. | Jana Kilińskiego 2 | Łódź 91-421 | Poland | [email protected]